1 / 3

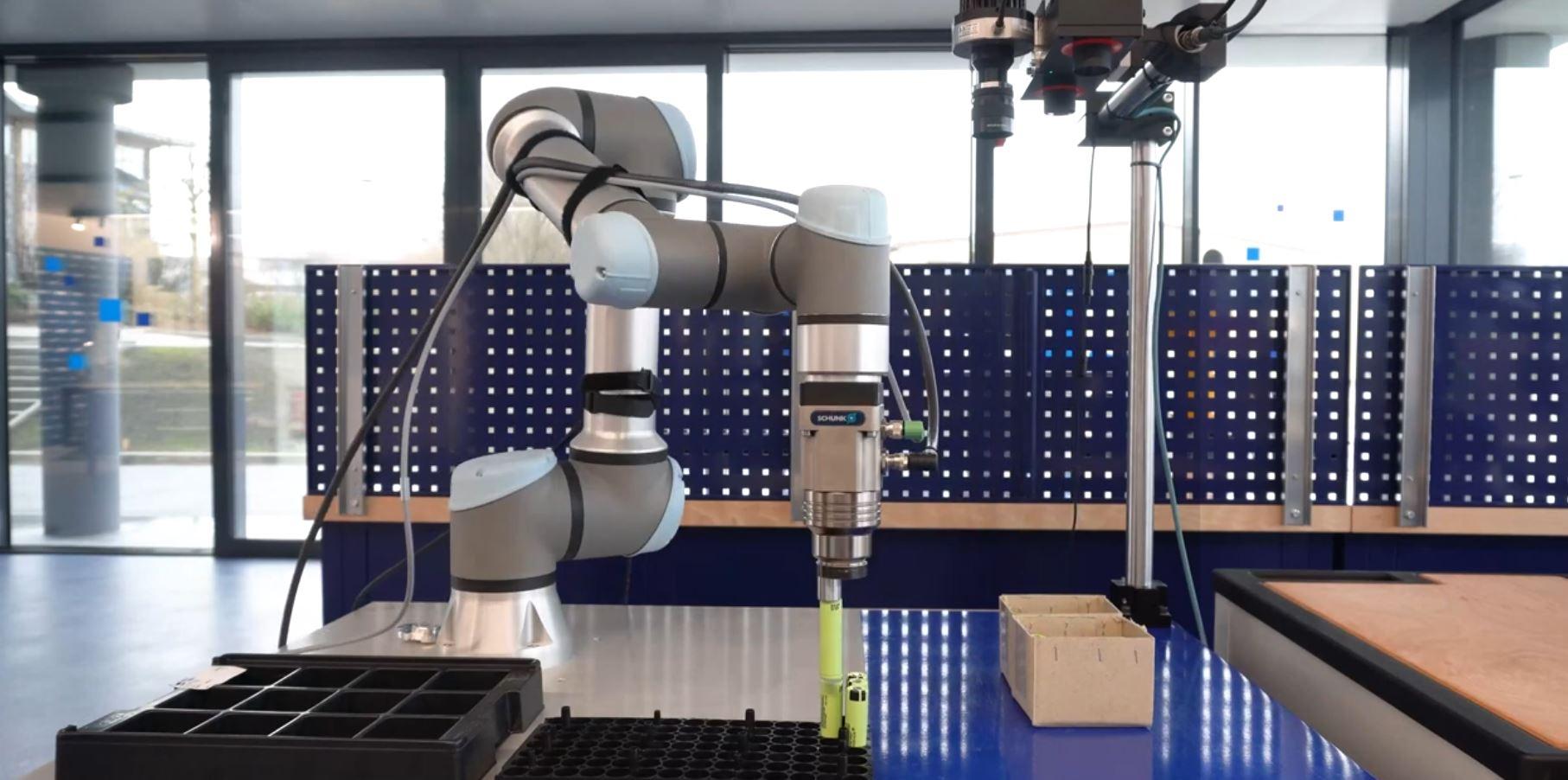

1 / 3Automated grinding machine for craft businesses

Hardware Price:

ROI

12 - 24

months

DOF

7

Max. payload

3

kg

Automated Sanding with igus Components: Efficiency in Skilled Craftsmanship

Sanding is an essential yet unpopular task in craftsmanship, often performed manually and requiring significant effort. To address challenges like employee reluctance and the ongoing shortage of skilled labor, the moduco GmbH automated this sanding process using components from igus. The system is designed to handle diverse workpieces, regardless of their material or shape, significantly reducing manual work and increasing efficiency.

What is the Application?

The automated solution replaces manual sanding with a robotic system that can sand various types of workpieces, providing consistent results while reducing employee workload.

What are the Advantages of the Solution?

Reduced Manual Effort: Employees save time and energy, reallocating focus to high-value tasks.

Skill Shortage Mitigation: Automation compensates for a lack of skilled personnel.

Consistency: Ensures even sanding across diverse workpiece types.

What are the Advantages of the Robot?

Using igus components, the automated sanding solution delivers:

Versatility: Adapts to different materials and shapes with ease.

Low Maintenance: Durable, lubrication-free components ensure long-term reliability.

Enhanced Productivity: Accelerates the sanding process while maintaining quality.

Addressing Labor Challenges Through Automated Sanding

This automated sanding system combines efficiency with flexibility, tackling the skilled labor shortage while improving workflow quality. By using igus components, the moduco GmbH innovation empowers craftsmanship businesses to modernize operations, reduce costs, and increase productivity without compromising precision.

3 Components